![]()

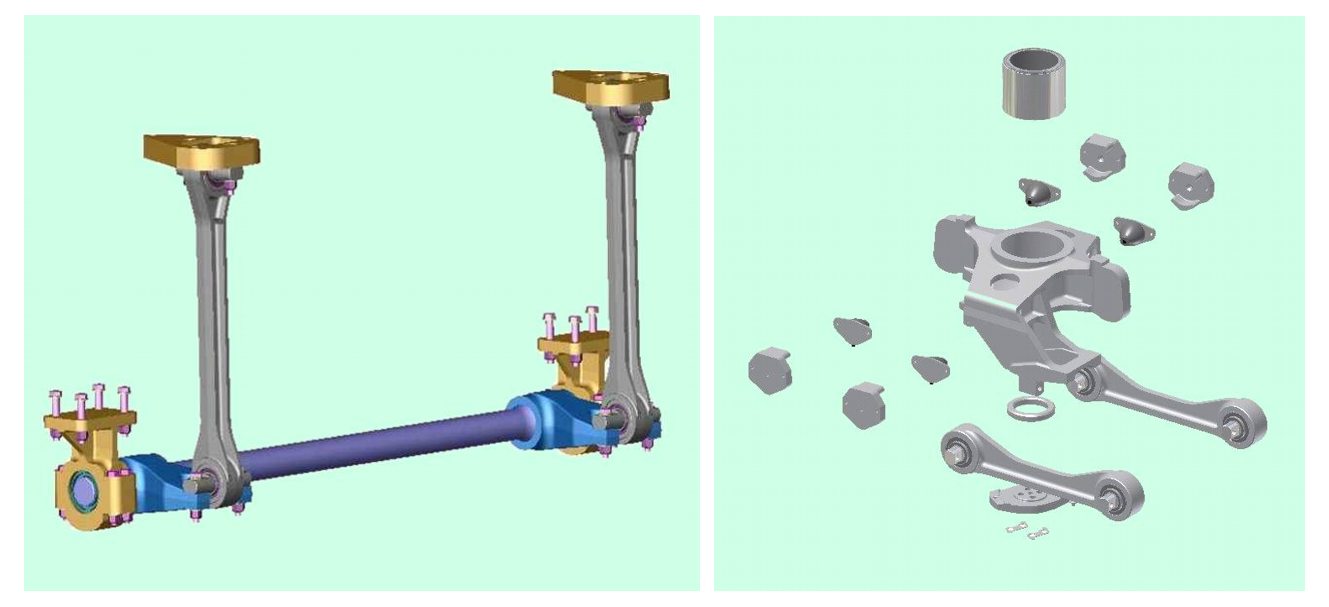

Rail Suspension

Railway Traction Centre Assemblies

Used to transfer the traction loads between the bogie and body and provide the body to bogie pivot rotation during rail curvature manoeuvres.

Designs are produced to meet the operating and proof loads and evaluated using Finite Element techniques in order to achieve the optimum stress conditions. The resulting solutions, produced and monitored using well proven manufacturing processes and in-house test facilities, provide the customer with a cost effective assembly package that will operate for the design life of the vehicle.

Railway Anti-Roll Bar Assemblies

A stability mechanism used to control the rolling characteristics of a railway vehicle. All vehicles need to provide the best possible ride characteristics but at the same time operate within the safe limits of the operating gauge.

The assemblies consist of torsion bars, levers, links and support bearings, in various styles, all of which as an assembly provide the required roll stiffness and vertical ride characteristics necessary to meet the best operating conditions.

Designed and validated to meet the customerís application requirements.

Roll bars are manufactured using various processes including, forging, bending, heat treatment and the final machining of the hardened material. Assemblies are offered as either single part or three piece, where the separate levers are shrunk onto the torsion bar.

The final assembly is completed and tested in-house, using experienced personnel and effective controls.